As data centers face increasing power shortages driven by AI and cloud computing demands, gas turbines and gas engines have emerged as critical backup and supplementary power solutions. Both technologies offer proven reliability in distributed generation, but each comes with distinct advantages and limitations. This article examines the key differences between gas turbines and gas engines to help data center operators choose the right technology for their power needs

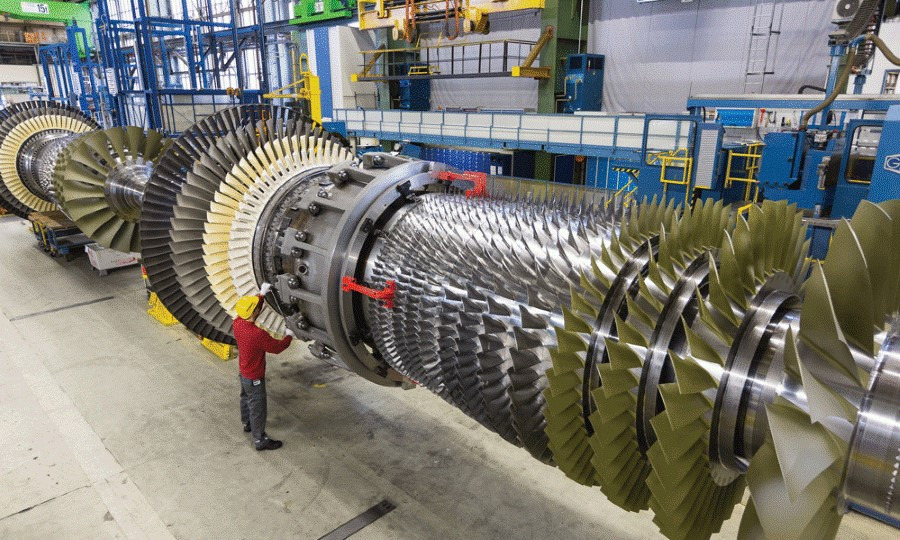

Gas Turbine

A gas turbine is a combustion engine that generates power through the continuous burning of compressed air and fuel. Operating on the Brayton cycle, it converts fuel—primarily natural gas—into mechanical energy, which drives an electrical generator to produce electricity.

The process works as follows: air is compressed and mixed with fuel, then ignited in the combustion chamber. This combustion creates extremely high-temperature, high-pressure gases that expand rapidly through the turbine blades, causing them to rotate at high speeds. The rotational energy is then transferred to the generator shaft.

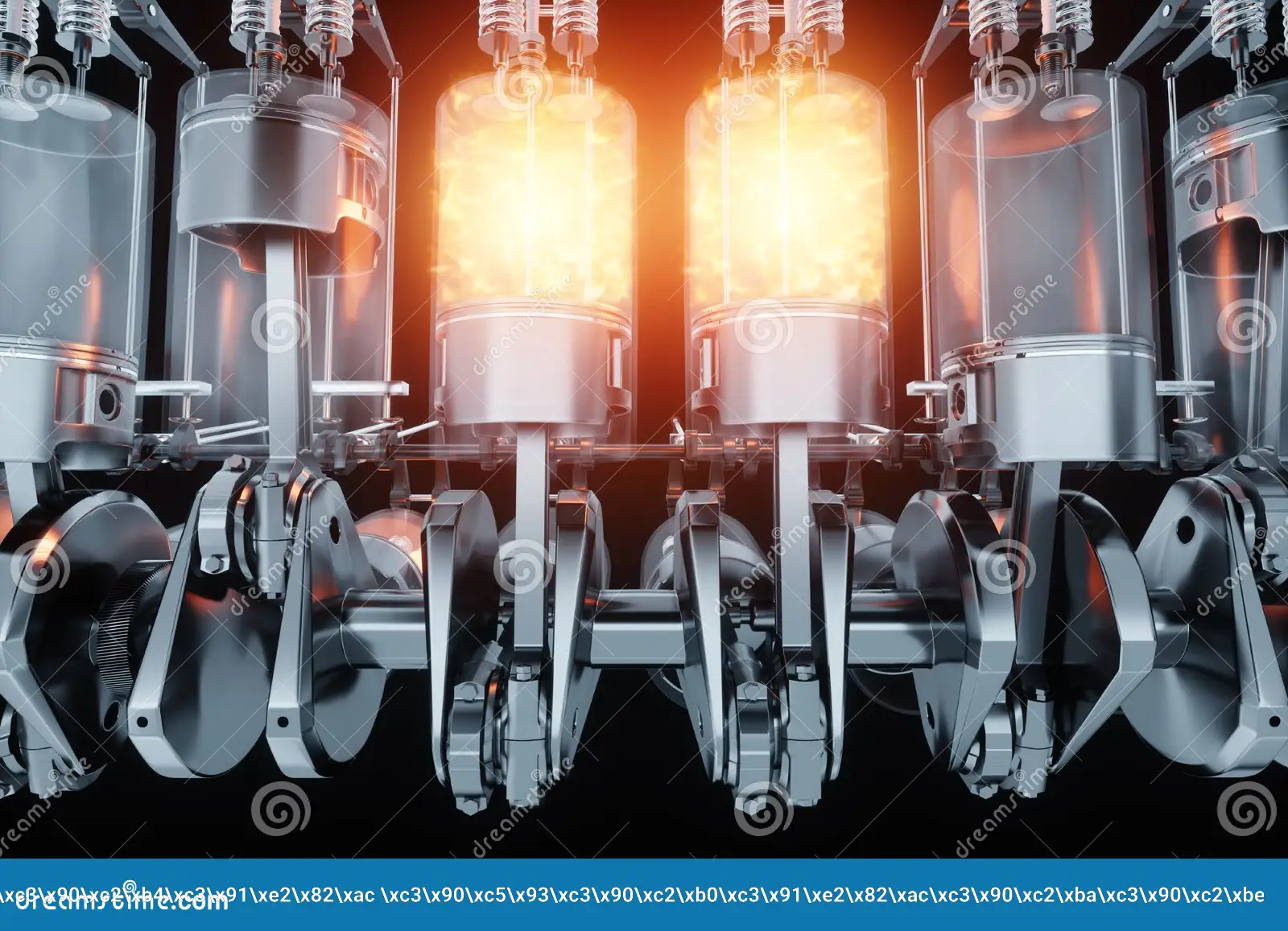

Gas Engine

A gas engine is an internal combustion engine that operates on the Otto or Diesel cycle, converting gaseous fuels directly into mechanical energy through controlled combustion within cylinders. Unlike gas turbines, gas engines use reciprocating pistons rather than continuous flow combustion.

The operational principle involves compressing a fuel-air mixture in cylinders, igniting it to create rapid expansion, and converting this linear motion into rotational energy through a crankshaft. Each engine unit connects to its own shaft, which drives a dedicated electrical generator. In industrial and data center applications, multiple gas engine units are often deployed in parallel configurations to create modular generating sets with high redundancy and operational flexibility.

Gas engines are available in standardized, commercially manufactured units ranging from 100 kWe to 20 MWe, making them cost-effective and scalable compared to custom-built central power plants. Their modular nature allows for incremental capacity expansion and improved maintenance scheduling—critical advantages for data center operators requiring high availability.

Gas Turbine VS. Gas Engine

There is a description of the difference between gas turbines and gas engines by considering several factors. Various factors, like those mentioned, are taken into account while selecting a gas turbine or a gas engine for a particular application.

The following factors show the main differences between gas turbines and gas engines.

Electrical Efficiency

- Gas turbine efficiencies range between 29 and 33%.

- Gas engine efficiencies range between 48.5% and 49%.

Energy Ratio of Cogeneration

- In a gas turbine, the energy ratio of cogeneration consists of electricity (33 percent), steam (50 percent), and loss (20 percent).

- In a gas engine, the energy ratio of cogeneration consists of electricity (49 percent), steam (15 percent), hot water (13 percent), low-temperature water (10 percent), and loss (13 percent).

Type of Heat Needed

- In the gas turbine, mostly steam provides the needed heat.

- In the gas engine, hot water and some steam provide the needed heat.

Total Efficiency of Cogeneration

- The gas turbine operates at 80% to 83% total efficiency of cogeneration.

- The gas engine operates at 63.5% to 77% total efficiency of cogeneration.

Electrical Efficiency (Partial Load)

- The electrical efficiency of the gas turbine is good.

- The electrical efficiency of the gas engine is very good.

Exhaust Heat

- The gas turbine has a high exhaust gas temperature and amount.

- The gas engine has a low exhaust gas temperature

NOx Emissions (O2=15%)

- In a gas turbine, NOx emission is about 15 to 25 ppm.

- In gas engines, NOx emission is about 57 ppm.

- - Modern gas turbines with DLN technology: 9-25 ppm

- - Gas engines (lean-burn): 45-57 ppm

- Note: Actual emissions vary significantly based on technology generation, control systems, and operating conditions

Vibration

- The vibration of the gas turbine is ultra-low.

- The vibration of the gas engine is low.

Machine Size

- Gas turbines: Available in larger sizes (1-300+ MW per unit, with typical installations ranging from 30-200 MW)

- Gas engines: Available in smaller, modular sizes (typically 0.3-20 MW per unit)

| Range | Space Advantage | Remark |

| <20MW | Gas Engine | Modular flexibility, distributed placement, containerization |

| 20-100MW | Situational | Depends on site characteristics and operational requirements |

| >100MW | Gas Turbine | Overwhelming power density (22x), smaller footprint |

'Data Center > Data Center' 카테고리의 다른 글

| Data Center] 한국에서는 시공사가 설계+공사를 수행할 수 없나요? (0) | 2026.01.25 |

|---|---|

| Gas Engine vs Fuel Cell: Comparison for Data Center Power Solutions (0) | 2025.12.04 |

| 연료전지 데이터센터 적용관련 Q&A (0) | 2025.11.28 |

| 연료전지 개요와 Type별 특징 (3) | 2025.11.25 |

| AI Datacenter 에 필요한 Load(부하) 특성 _ Part 6_(LLM Inference) (0) | 2025.07.21 |